Author: CHOCOMACH

January 09, 2024

3342

On the last day of 2023, through the joint efforts of members of CHOCOMACH team, 7 sets of Xinzhaofeng YZW fully automatic walnut kernel continuous hydraulic cold pressing oil production lines ordered by Xinjiang customers were dispatched to the beautiful Xinjiang Province and will soon start a new era. journey.

CHOCOMACH YZW automatic walnut kernel continuous hydraulic cold pressing production line is ready for loading ↑

CHOCOMACH YZW automatic walnut kernel continuous hydraulic cold pressing production line main press installation ↑

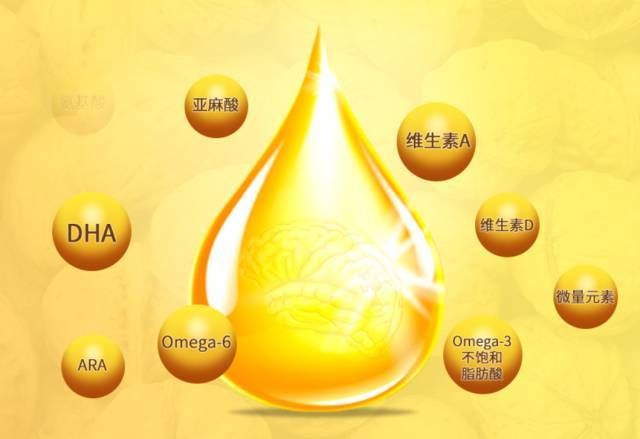

【Walnut Kernel Ingredients】

The fat content in walnut kernels is as high as about 65%, and the unsaturated fatty acids in the fatty acid composition are more than 90%, and there is a certain amount of linolenic acid. The intake of unsaturated fatty acids has a positive effect on reducing human serum cholesterol levels and preventing atherosclerosis and thrombosis. Walnut oil is a special oil for high-grade health care. In addition to high-quality fat, walnut kernels also contain about 15% high-quality protein and about 10% sugar. Walnut kernels need to be further developed for resource utilization.

[Walnut kernel processing, utilization and technology]

In the past ten years, food science and technology workers have continued to conduct in-depth research and practice on the industrial processing of walnuts. At present, the main processed products of walnuts include walnut oil, liquid beverages (walnut milk, etc.), walnut protein powder, and canned walnuts (amber walnut kernels, etc.) . Walnut oil is a high-grade edible oil. Using walnuts as raw materials to produce oil is one of the main directions for deep processing of walnuts. There are two types of oil production processes that have been used at present: one is to use the traditional mechanical pressing process to extract oil; the other is to use the pre-pressing-leaching process. Below we mainly introduce the specific process of the first pressing oil production method:

Walnut fruit peeling → Kernel shell separation → Oil extraction → Cake removal → Filtration → Canning → Products

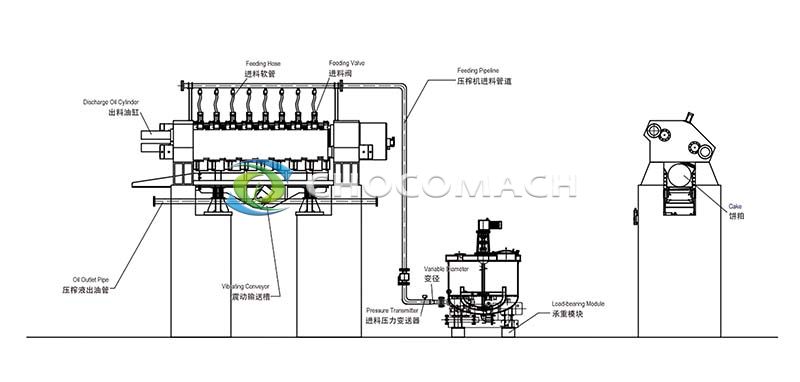

[Two feeding forms of CHOCOMACH press]

Solid particle feed and fluid slurry feed.

(1) Each pressing chamber of the solid particle feeding machine is equipped with an independent feeding bin. The upper part of the feeding bin is equipped with a quantitative feeding device and is designed with an electric feeding valve to ensure that there is no bridge during the feeding process.(YZW PRESS)

(2) The fluid slurry machine is fed by a cam rotor pump or a high-pressure plunger pump. The feed pipe is equipped with a pressure transmitter, which can control the feed amount through pressure.(YZYW PRESS)

[Technical Characteristics of CHOCOMACH Automatic Horizontal Press Chamber Hydraulic Oil Press]

YZYW automatic horizontal press box/YZW press chamber hydraulic oil press can realize solid particle and fluid slurry pressing in two working conditions. It has automatic feeding, automatic quantitative feeding, automatic pressing, automatic cake discharging, and automatic cake discharging. To the conveyor, it has the function of automatic sorting and recovery.

CHOCOMACH YZW automatic walnut kernel continuous hydraulic cold pressing 7 production line main presses are ready for installation↑

Previous ← Automatic Hydraulic Oil Press YZW/S

Next → Automatic Hydraulic Cocoa Butter Press YZYW

Service Tel:

+86 136 0865 6963

+86 199 3799 5959

0086 0379-61127277

Email:

chocooilpress@gmail.com info@chocomach.com

Wechat:

WhatsApp:

+86 199 3799 5959