Author: CHOCOMACH

October 13, 2025

33092

The 2025 International Sesame Industry Technology Symposium was held in Zhengzhou province,china. CHOCOMACH is leading the industry upgrade with its hydraulic oil press technology.

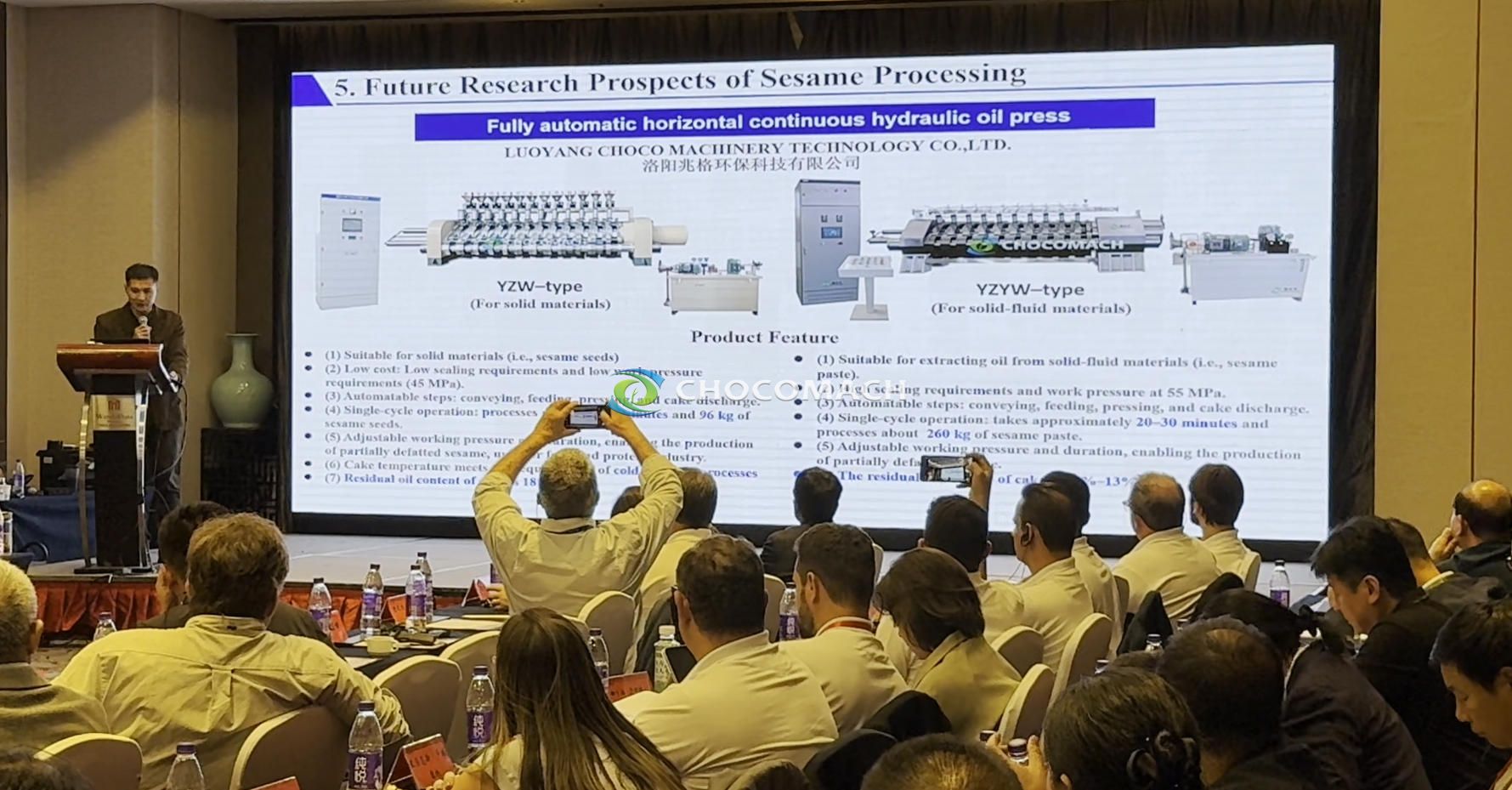

The 2025 International Sesame Industry Technology Symposium was recently held in Zhengzhou province,china. Over 300 industry chain representatives, experts, and scholars from over 20 countries and regions gathered for in-depth discussions on key topics such as technological innovation in sesame deep processing and intelligent production. Luoyang Zhaoge Environmental Protection Technology Co., Ltd., a leading domestic company in hydraulic pressing equipment, was invited to participate. Their presentation of their fully automatic horizontal hydraulic pressing production line and sesame processing solutions using the CHOCOMACH brand's fully automatic hydraulic oil press attracted widespread attention in the industry.

Deeply rooted in hydraulic technology, a long-standing foundation forges innovative strength.

CHOCOMACH's participation in the symposium stems from its extensive technical expertise and contributions to the industry. Leveraging the technological foundation of the Ruyang County Hydraulic Machinery Plant in Henan Province, established in 1958. the company has grown into a high-tech enterprise integrating R&D, production, and service since its founding in 2018. The company has received numerous prestigious certifications, including "Henan Province's First Major Technical Equipment" and "Henan Province's Specialized, Refined, and Innovative Small and Medium-sized Enterprise," and holds a total of 23 patents. Through industry-university-research collaborations with institutions such as Henan Institute of Technology and COFCO Engineering, its technological achievements have been successfully applied to the processing of various oilseeds, including sesame and walnuts, with products exported to Southeast Asia and Europe.

Core Technology Unveiled, Addressing Pain Points in the Sesame Processing Industry

During the technology sharing session, the director of CHOCOMACH detailed the innovative breakthroughs in the fully automatic horizontal hydraulic pressing line, addressing the industry's challenge of balancing high nutrient retention with efficient production.

Low-temperature Precision Pressure Control Technology: Utilizing a high- and low-pressure dual-pump system, the system achieves high pressures up to 55 MPa, material pressures up to 90 MPa, and operating pressures up to 2860 T. Combined with low-temperature constant temperature control, this technology enables full cold pressing. Tests have shown that this technology reduces sesame protein denaturation to ≤5% and increases vitamin E and polyphenol retention by 30%, perfectly meeting the nutritional requirements of high-end sesame oil.

Continuous Production Breakthrough: Utilizing a 4-22-chamber tandem design and a PLC intelligent control system, the entire process of loading, pressing, and cake unloading is fully automated, requiring only one operator to operate each unit. This solves the labor-intensive, intermittent production challenges of traditional equipment. Based on data from a similar walnut kernel production line, this system can process up to 45 tons of oil per 24 hours, with a cake oil residue rate exceeding national standards.

Green and low-carbon design: The entire machine consumes only 18.5kW of energy, and its circulating water utilization rate exceeds 95%, significantly reducing energy consumption compared to traditional equipment and aligning with the industry's green development trends.

CHOCOMACH Brand Empowers Multi-Scenario Sesame Processing Solutions

Targeting the needs of businesses of varying sizes, CHOCOMACH is promoting its own-brand "CHOCOMACH" fully automatic hydraulic oil press production line. Leveraging its core "filter cloth-free horizontal press" technology, this series of equipment offers three key advantages in sesame processing:

Flexible Adaptability: Available in multiple models, including the YZL-270/300/325. YZW, YZYW, YZBW, YZQW, and HPFB, the single-load capacity can meet the "just-in-time processing" needs of small workshops, the large-scale production of medium-sized enterprises, and the scaled-down, automated production requirements of large oil mills.

Quality Controllability: The end-face oil outlet design, combined with a multi-stage filtration system, significantly improves crude oil purity, reducing subsequent refining costs. It is particularly suitable for high-end small-mill sesame oil processing and low-temperature cold-pressing of raw sesame oil.

Cost Competitiveness: Energy-efficient and efficient, with minimal equipment wear and tear and a low failure rate, and a global after-sales service network, effectively reducing operational and maintenance costs.

Strong Industry Resonance, Accelerating Technology Upgrades

At the seminar, numerous experts highly praised CHOCOMACH's technological achievements. A representative from the China Chamber of Commerce for Import and Export of Foodstuffs, Native Produce, and Animal Products noted that this technology perfectly aligns with the development direction of sesame deep processing: "efficient extraction, intelligent production, and environmentally friendly practices." Its low residual oil content and high nutrient retention will help Chinese sesame products break through quality barriers in international markets like the EU. Major grain and oil companies in Jiangsu and Henan have expressed interest in collaboration, and commissioning of the relevant production lines is about to begin.

A representative from CHOCOMACH stated that the company will leverage this seminar to further deepen its research and development of sesame processing technology. The company plans to launch specialized pressing equipment for sesame peptide extraction by 2026. further improving its "seed oil and sesame powder co-production" solution and providing technical support for the high-quality development of the global sesame industry.

Service Tel:

+86 136 0865 6963

+86 199 3799 5959

0086 0379-61127277

Email:

chocooilpress@gmail.com info@chocomach.com

Wechat:

WhatsApp:

+86 199 3799 5959