Author: CHOCOMACH

January 15, 2026

8802

I. Industry Dilemmas Await Resolution, an All-Round Equipment Comes into Being

With the upgrading of healthy consumption, the markets for cold-pressed oil and high-end hot-pressed oil have expanded in both directions. In 2024. the market size of China's cold-pressed oil industry reached 18.63 billion yuan, and the demand for hot-pressed products such as sesame oil and cocoa butter also achieved a year-on-year growth of 12%. However, the technological limitations of traditional equipment have always restricted the industry development: the cold pressing of woody oilseeds relies on inefficient intermittent hydraulic presses, while hot pressing is plagued by the pain points of manual cake making and high residual oil rate.

The Full-Automatic Hydraulic Oil Press (Model YZYW) precisely breaks through this dilemma. It not only pioneers the continuous production mode for cold pressing of woody oilseeds such as walnuts and tea seeds, but also optimizes the hot pressing process of sesame and cocoa. It fills the technical gap in the dual scenarios of "cold pressing + hot pressing" for high-oil-content oilseeds, becoming a powerful tool for industrial upgrading that covers multiple product categories.

II. Product Features: Customized by Process, Adapting to the Needs of Different Oilseeds

1. Precise Process Zoning: Nutrient Retention in Cold Pressing, Flavor Enhancement in Hot Pressing

Cold Pressing Process for Woody Oilseeds (Walnuts/Tea Seeds)

Without high-temperature roasting, the raw materials are directly crushed after cleaning and drying, and processed through low-temperature pulping (temperature ≤ 45℃), avoiding the loss of active substances such as unsaturated fatty acids and vitamins in woody oilseeds. The homogenizing tank feeds materials into the press at a constant temperature of 40-50℃, and the press box jacket is insulated with 1kg low-pressure steam (temperature 60℃±5℃). A single working cycle takes 40 minutes, and the oil content of the meal is ≤ 8%, meeting the core demand of "low-temperature nutrient preservation" for woody oilseeds.

Hot Pressing Process for Sesame/Cocoa

Sesame is deeply roasted at 220℃ and then cooled to 60℃, and processed into fine slurry with a 150-200 mesh pass rate of over 90% by a pulping machine; cocoa beans are roasted, crushed and ground into cocoa slurry. Both raw materials are heated to above 105℃ in the homogenizing tank before being fed into the press. The press box jacket is heated to 110℃ (±5℃) with 2kg steam, and a single working cycle takes 30 minutes. The oil content of sesame meal is ≤ 13%, and that of cocoa meal is 10%-12%, fully stimulating the natural aroma and flavor substances of the raw materials.

2. Innovative Fluid Feeding, Universally Adaptable to Both Cold and Hot Pressing Processes

Aiming at the low viscosity characteristics of cold-pressed slurry (walnuts/tea seeds) and the high viscosity characteristics of hot-pressed paste (sesame/cocoa), the equipment uniformly adopts cam rotor pumps or high-pressure plunger pumps for feeding, equipped with pressure transmitters for real-time monitoring. It intelligently adjusts the pump speed to adapt to the fluidity of different materials, ensuring accurate quantitative supply and avoiding the problems of feeding blockage in cold pressing and uneven feeding in hot pressing.

3. Zoned Temperature Control Design, Ensuring Process Stability

The press chamber is built with a dual-mode temperature control system: in cold pressing mode, it maintains a stable low-temperature environment of 60℃±5℃ through 1kg low-pressure steam plus circulating water cooling; in hot pressing mode, it accurately controls a constant temperature of 110℃±5℃ through 2kg high-pressure steam heating. The dual modes can be freely switched, which not only meets the low-temperature requirements of cold pressing for woody oilseeds, but also adapts to the high-temperature needs of hot pressing for sesame and cocoa, ensuring the consistency of product quality under different processes.

Extracted from Characteristic Oilseeds Processing in China, edited by Liu Huamin, China Light Industry Press

III. Technical Advantages: Five Major Breakthroughs, Meeting the Core Needs of Both Cold and Hot Pressing

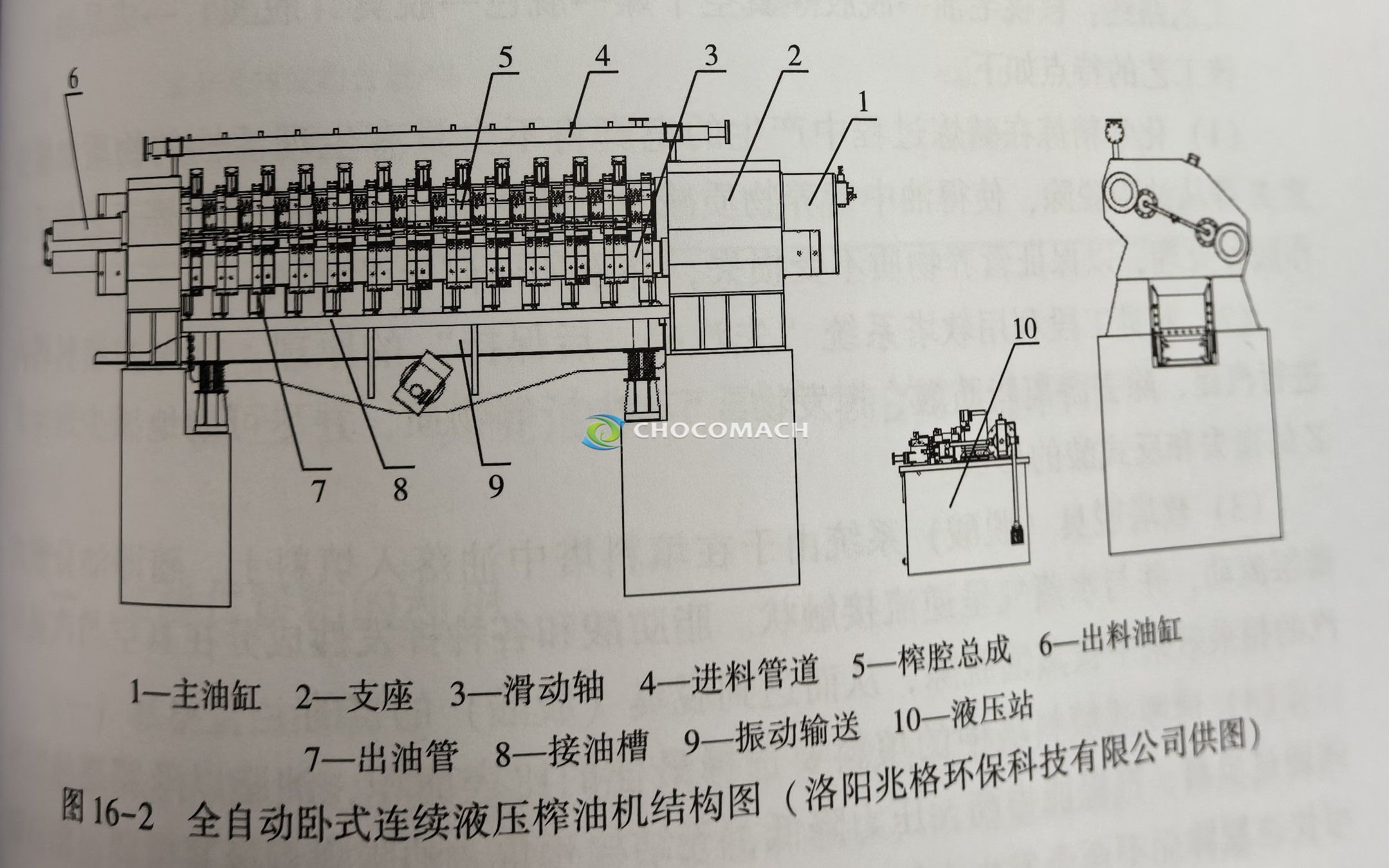

1. Horizontal Structure + End-Face Oil Discharging, Dual Efficiency Improvement for Cold and Hot Pressing

The innovative horizontal press box structure separates the loading and pressing systems independently. The "end-face oil discharging" design shortens the oil path, reduces the oil flow resistance at low temperatures during cold pressing, and accelerates the release of high-temperature oil during hot pressing. Compared with traditional equipment, the cold pressing efficiency is increased by 35%, and the hot pressing efficiency is increased by 28%, which is suitable for large-scale production.

2. Filter Cloth-Free Filtration, Pure Meals for Both Cold and Hot Pressing

The unique filtration structure completely abandons filter cloth/filter bag for cake making. During cold pressing, it avoids protein contamination of woody oilseed meals (such as walnut meal); during hot pressing, it prevents fiber residues in sesame/cocoa meals. The protein purity of meals from both processes reaches over 92%. Cold-pressed meals can be directly used for protein extraction, and hot-pressed meals can be reprocessed into feed or food raw materials.

3. Ultra-High Pressure Hydraulic System, Dual Reduction of Residual Oil in Cold and Hot Pressing

The world-leading hydraulic pump valve and ultra-high pressure proportional valve system can reach a pressure of 45-55MPa. It customizes the "low-pressure pre-pressing + high-pressure slow pressing" curve for cold-pressed materials (high hardness), and the "high-pressure fast pressing + low-pressure finishing" curve for hot-pressed materials (high viscosity). The residual oil rate of cold-pressed meals is ≤ 10%, and that of hot-pressed meals is ≤ 12%, which is far lower than the industry average.

4. Fully Closed Operation, Dual Guarantee of Cleanliness for Cold and Hot Pressing

Whether in cold pressing or hot pressing, the materials run in a closed press chamber throughout the process without contact with personnel. During cold pressing, it avoids the contamination of active ingredients by external impurities; during hot pressing, it prevents the oxidation and deterioration of high-temperature oilseeds. It ensures that cold-pressed oil is clear without precipitation, and hot-pressed oil is rich in flavor without peculiar smell, both complying with food-grade hygiene standards.

5. PLC Intelligent Control, One-Key Switch Between Cold and Hot Pressing Processes

The PLC control system is equipped with a touch screen operation interface, built-in two sets of preset programs for cold pressing and hot pressing, which can switch process modes with one key. Parameters such as temperature, pressure and feeding volume can be adjusted in real time with visualization. The system supports centralized data collection and remote transmission, with a fault response time of < 0.5 seconds. It accurately controls temperature to prevent nutrient loss during cold pressing, and accurately controls pressure to prevent material charring during hot pressing.

IV. Industry Value: Full Category Coverage, Leading the New Direction of Oilseed Processing

The "cold-hot dual adaptation" feature of Model YZYW Full-Automatic Hydraulic Oil Press completely breaks the "single process limitation" of traditional equipment: for healthy cold-pressed products such as walnut oil and tea seed oil, it locks in nutrients through low-temperature technology, helping enterprises seize the high-end healthy food market; for flavored hot-pressed products such as sesame oil and cocoa butter, it stimulates aroma through precise temperature control, meeting the high-quality needs of the food processing and condiment industries; for large-scale oil factories, it realizes "one machine for multiple uses" and reduces the equipment investment cost of multi-category production.

In the growth track with an annual growth rate of 14.7% for cold-pressed oil and 12% for high-end hot-pressed oilseeds, this equipment not only solves the pain points of "low efficiency" in traditional cold pressing and "high labor intensity" in hot pressing, but also promotes the transformation of oilseed processing from "single category" to "full category coverage" and from "extensive production" to "precision processing", providing core support for the upgrading of the edible oil industry under the Healthy China strategy.

Service Tel:

+86 136 0865 6963

+86 199 3799 5959

0086 0379-61127277

Email:

chocooilpress@gmail.com info@chocomach.com

Wechat:

WhatsApp:

+86 199 3799 5959